- Hydraulic Core Drill

- HCDU-5 Hydraulic Core Drilling Rig

- HCDF-6 Hydraulic Core Drilling Rig

- Spindle Type Core Drills

- Core Drill Rig

- Drilling Rig for Geothermy,Water Well and Coalbed Methane

- Coal Bed Methane Drilling Rig

- Water Well Drilling Rig

- Geothermal Drilling Rig

- Truck Mounted Drilling Rig

- DPP100-4 Truck Mounted Drilling Rig

- Engineering Drill Rig

- GPF2000D Engineering Drilling Rig

- Mud Pump

- BW1200A Mud Pump

- 3NB1300 Mud Pump

- Drill Tower

- SG Series Drill Tower

- AG Series Drill Tower

- Fishing Tools

- Recovering Taps

- High Speed Drilling Swivel

- Drill Hydraulic Jack

- NY-3 Hydraulic Screw Machine

- Petroleum Machinery

- ZP175 Drill Rotary Table

- Sucker Rod and Sucker Rod Coupling

- Chemical Industry Machinery

- Pressure Vessel

- Steel Structure Products

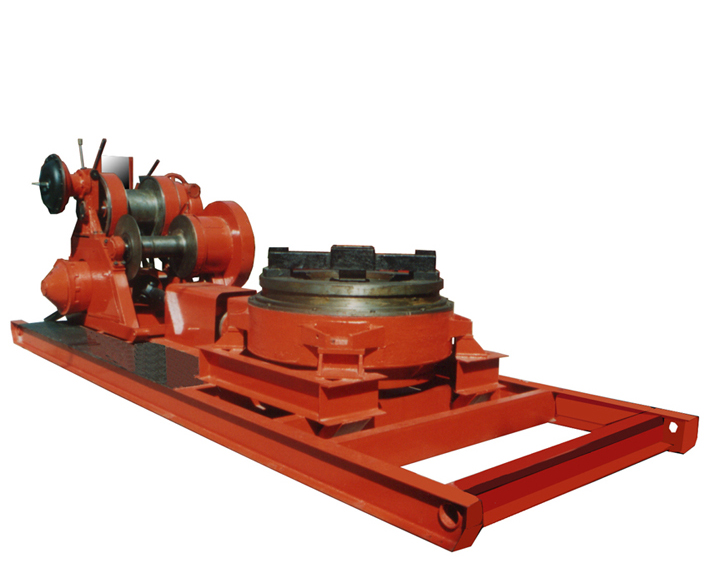

Water Well Drilling Rig SPS600

SPS600 type drill rig is suitable for the drilling work (within 600 m) in soil, rock and gravel layer. It can be used in the drilling of water well and the exploitation of shallow geothermal energy, petroleum, natural gas and salt. Mechanical transmission is adopted in this rig. Rotary table is used to drive the drill tools. This water well drilling rig has a main winch and an assistant winch. Trussed A-shaped derrick or quadrangle derrick is used as drill tower.

Features1. This drill rig is very easy to disassemble and transport.

2. This product features large torque, great hoisting capacity and wide range of rotating speeds.

3. This water well drilling rig is capable of both direct and reverse circulation drilling.

4. We supply high precision drill rigs at very competitive prices. These rigs are designed to be durable and capable of running in the countries of the most complex geological conditions.

1. Dig slurry pool and slurry circulating channel and stir the slurry.

2. Check the diesel engine and mud pump of the drilling rig.

3. Check if all components are stable and reliable.

4. Disconnect the clutch of the diesel engine, the clutch of the mud pump, the V-belt pulley and the feeding hand wheel. Check the gearbox, the winches, cardan shaft and the rotary table for jam phenomena.

5. Lubricate the parts of the drilling rig according to the lubrication standard and diagram.

1. The surface of the drill rig should remain clean. Clean the slurry, dirt and oil sludge frequently.

2. Check the temperature rise condition of the rolling bearing and each friction piece. The temperature of the bearing should exceed 70°. If the temperature exceed the requirement, operator should stop this water welll drilling rig immediately and check.

3. If knock sound and abnormal sounds appear when the gears are running, operator should stop the truck and check.

4. If oil impregnate and leakage occurs in any sealed part, operator should stop the machine and solve the problem.

Notice: For specific operation, please refer to the detailed information of the product manual.

| Drilling Depth (m) | 600 |

| Rotary Table Normal Diameter (mm) | φ605 |

| Rotating Speed (r/m) | 42, 75, 134 |

| Drill Rod inside Hole | φ73, φ89 |

| Kelly(mm × mm × mm) | 108 × 108 × 8000; 108 × 108 × 12000 |

| Main Winch | |

| Single Wire Hoisting Capacity (KN)` | 35 |

| Rated Load of Big Hook (KN) | 210 |

| Big Hook Hoisting Speed (m/s) | 0.15-0.47 |

| Pulley Block Type | 3 × 3 |

| Steel Wire Diameter (mm) | φ20-φ21.5 |

| Assistant Winch | |

| Rated Single Wire Hoisting Capacity (KN) | 15 |

| Max. Single Wire Hoisting Capacity (KN) | 20 |

| Single Wire Hoisting Speed (m/s) | 0.58 |

| Steel Wire Diameter (mm) | φ9.8 |

| Power (KW) | 37 |

| Main Machine Weight (t) | 5.5 |

-

- Water Well Drilling Rig SPS1000

- SPS1000 type geothermal drilling rig is a rotary-table type drilling machine. It has mechanical transmission system. This rig is mainly used in the exploitation of underground water, shallow geothermal energy, shallow petroleum, natural gas and salt. It has the functions of direct and reverse circulation drilling with mud and multi-process drilling with air.

Español

Español  Português

Português  Русский

Русский