- Hydraulic Core Drill

- HCDU-5 Hydraulic Core Drilling Rig

- HCDF-6 Hydraulic Core Drilling Rig

- Spindle Type Core Drills

- Core Drill Rig

- Drilling Rig for Geothermy,Water Well and Coalbed Methane

- Coal Bed Methane Drilling Rig

- Water Well Drilling Rig

- Geothermal Drilling Rig

- Truck Mounted Drilling Rig

- DPP100-4 Truck Mounted Drilling Rig

- Engineering Drill Rig

- GPF2000D Engineering Drilling Rig

- Mud Pump

- BW1200A Mud Pump

- 3NB1300 Mud Pump

- Drill Tower

- SG Series Drill Tower

- AG Series Drill Tower

- Fishing Tools

- Recovering Taps

- High Speed Drilling Swivel

- Drill Hydraulic Jack

- NY-3 Hydraulic Screw Machine

- Petroleum Machinery

- ZP175 Drill Rotary Table

- Sucker Rod and Sucker Rod Coupling

- Chemical Industry Machinery

- Pressure Vessel

- Steel Structure Products

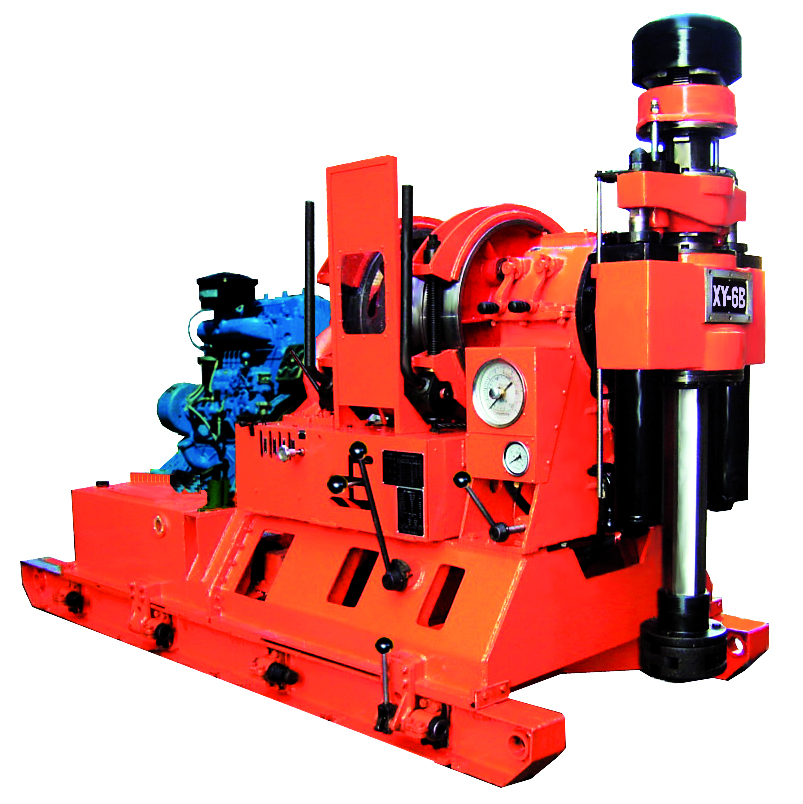

XY-6B/6N Core Drill (Depth 1000-2000M)

XY-6B/6N type geological drill rig is a spindle type drilling machine with mechanical and hydraulic transmission. It is a type of deep drilling equipment used in the fields of geological prospecting, hydrology water well, coalfield prospecting and oil and natural gas exploitation. This spindle type Geological Drill Rig integrates the advantages of all spindle type hydraulic drilling rigs. It can drill small diameter holes as well as large diameter holes. XY-6B/6N type core drill machine is an ideal equipment for deep drilling of geological prospecting.

Main Features1. The spindle has high rotating speed with a wide range of optional speeds.

2. The winch of the core drill machine has a water brake. The brake can lower the drill tool smoothly.

3. Oil-dipped type clutch starts smoothly. It has a brake device.

4. The hydraulic operating system has an exclusive valve port. The valve can be used when the machine is working with breakout machine.

5. The core drill machine has long forward and backward retracting distance. It makes working at hole mouth very convenient.

6. Normal diameter of the spindle is large. The spindle can fulfill various drilling techniques.

7. This spindle type Geological Drill Rig has moderate weight. It can easily be disassembled and transported.

Our XY-6B type core drill rig used by Shandong the Sixth Geological Team has fulfilled 2400.81 m deep drilling task in September 2009. The designed drilling depth of this hole is 2400 m. The drilling angle is 88° and the finished hole diameter is 75 mm. This Geological Drill Rig reaches high levels in technique, operation level and bearing capacity. The great drilling capacity of this spindle type core drill machine has been proved.

Attention1. The core drill machine should stay horizontal in installation process. The centre of spindle, pulley of the crown block and the hole center should be in a vertical line.

2. The chassis of the spindle type Geological Drill Rig should be fixed on the base of the drill tower with foundation bolt.

3. Before starting the core drill rig, operator should check every bolt and the connections of all fastening pieces.

4. Operator should check the oil injection according to oil pointer and add lubrication oil to each lubrication point.

5. All braking parts of the core drill machine should work reliably. The mating faces should remain clean.

1. Operators in each shift should check all fastening parts and clean every mating face. The core drill machine should be lubricated and oil leakage should be eliminated

2. The clutch and hand-operated oil pump check should be done every week

3. Workers should clean the oil box of the core drill rig and filter the oil every month. Hydraulic oil should also be checked. Please consult the detailed information of the manual in actual operation.

Before clients buying this core drill rig, our sales department would assist clients in designing optimum process and plan. We have a well-experienced and skilled customer service team.

The services mainly include:

1. We help clients to select suitable models of the equipment.

2. We can connect with technician training for clients.

3. We provide our clients with normal supporting products and rationally configured complete set of equipment.

XY-6B/6N type core drill rig would be delivered within 30 days.

Parameters of Spindle Type Geological Drill Rig| Drilling Depth (m) | 1000-2000-2000 |

| Drill Rod Diameter (mm) | φ50, φ60, φ89 |

| Spindle Rotating Speed (r/min) | Forward: 80, 175, 225, 260, 360, 490, 730, 1000; Reverse: 62, 170 |

| Torque (kN.M) | 5~6 |

| Cylinder Feeding Stroke (mm) | 600 |

| Cylinder Pulling Force (KN) | 200 |

| Cylinder Feeding Force (KN) | 150 |

| Cylinder Diameter (mm) | φ125 |

| Max. Single-Wire Hoisting Force (KN) | 60 |

| Winch Hoisting Speed (m/s) | 0.66, 1.44, 1.85, 2.13, 2.96, 4 |

| Reel Diameter (mm) | φ300 |

| Steel Wire Diameter (mm) | φ20 |

| Rope Capacity (m) | 140 |

| Retracting cylinder Stroke (mm) | 550 |

| Electric Motor | 55kW Y250M-4 Type |

| Diesel Engine | 100HP 4135AG Type |

| Gear Oil Pump | YBC45/80 Type, 8Mpa, 45L/mln |

| Weight (t) | 3.8 (not including driving part) |

| Dimensions (L×W×H) (mm) | 3450×1500×2250 |

-

- XB2000A Rotary Core Drill

- XU1000 type core drilling machine integrates the advantages of spindle type drilling rigs. It can be used in metal or nonmetal solid deposit exploitation. This Geological Drill Rig plays an un-replaceable role in the fields of geology, hydrology, metallurgy and coal field exploitations. This core drilling machine is has water brake and has a normally-open type clutch mechanism.XU1000 type core drilling machine integrates the advantages of spindle type drilling rigs. It can be used in metal or nonmetal solid deposit exploitation. This core ...

Español

Español  Português

Português  Русский

Русский