- Hydraulic Core Drill

- HCDU-5 Hydraulic Core Drilling Rig

- HCDF-6 Hydraulic Core Drilling Rig

- Spindle Type Core Drills

- Core Drill Rig

- Drilling Rig for Geothermy,Water Well and Coalbed Methane

- Coal Bed Methane Drilling Rig

- Water Well Drilling Rig

- Geothermal Drilling Rig

- Truck Mounted Drilling Rig

- DPP100-4 Truck Mounted Drilling Rig

- Engineering Drill Rig

- GPF2000D Engineering Drilling Rig

- Mud Pump

- BW1200A Mud Pump

- 3NB1300 Mud Pump

- Drill Tower

- SG Series Drill Tower

- AG Series Drill Tower

- Fishing Tools

- Recovering Taps

- High Speed Drilling Swivel

- Drill Hydraulic Jack

- NY-3 Hydraulic Screw Machine

- Petroleum Machinery

- ZP175 Drill Rotary Table

- Sucker Rod and Sucker Rod Coupling

- Chemical Industry Machinery

- Pressure Vessel

- Steel Structure Products

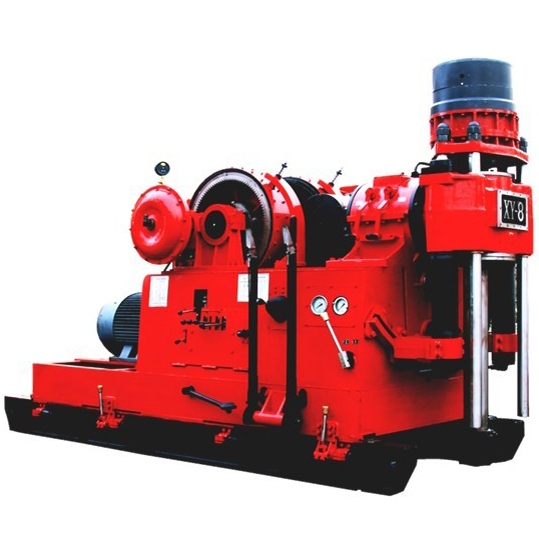

XY-8 Core Drilling Rig

XY-8 type core drilling rig is a deep hole core drill machine which can drill large normal diameter holes. This spindle type core drill rig has the characters of mechanical transmission, spindle rotation and hydraulic feeding. Its winch is horizontally arranged. This product usually uses diamond drill bit or hard alloy bit in drilling. Wire line coring is available.

Features and Advantages1. XY-8 type core drilling rig is designed with large power and large spindle torque.

2. The spindle has large normal diameter and double hydraulic feeding. The spindle has long stroke.

3. The chuck of this core drill machine has great clamping force.

4. The winch of the core drilling rig has a horizontal design. It makes rope arrangement very convenient. The winch has great hoisting force.

5. This machine has the advantages of wide drilling speed range, rational speed arrangement, large power configuration, large torque output and rotary table type structure.

6. XY-8 type core drilling rig is equipped with water brake which is agile, reliable and easy to operate.

7. This product is a lightweight core drill machine. It is steady and durable.

XY-8 type core drilling rig has a drilling capacity of 3000 m. It is mainly used in metallic or nonmetallic solid ore deposit prospecting, shallow oil and natural gas exploitation, tunnel ventilation and draining of mines and large hole foundation pile construction. It can drill both vertical holes and inclined holes. Shandong golden geology and mineral resources exploration co., ltd. has used our XY-8 type core drilling rig and achieved a 2500 m hole with 77° drilling angle. That is the deepest record at home.

Notes on Operation1. The clutch of the core drilling rig should be connected smoothly. It is prohibited to connect and disconnect the clutch ceaselessly.

2. When operating the oil-pressure clips to loose or clamp the drill rod, operator should stop the rotating spindle immediately.

3. Operator should pay attention to the pressure indicator of the core drilling rig.

4. The clutch must be disconnected before the operator moving the transfer case handle or gearbox handle. Changing gears when driving the machine is prohibited.

5. Before starting the rotating unit of the core drilling rig, operator should pull the drill tool off the hole bottom and connect the main clutch.

1. In each shift, operators should check every fastening part of the core drilling machine and clean all mating faces. Oil leakage should be eliminated.

2. Clutch and hand-operated oil pump should be checked each week.

3. Clients should clean the oil box, filter and hydraulic oil every month.

For detailed information please consult product manual in actual operation.

XY-8 type core drilling rig would be delivered in thirty days.

Parameters

| Drilling Depth(m) | 1000-3000 |

| Drill Rod Diameter under Machine (mm) | φ50.5 φ60 φ71 φ73 φ89 φ114 |

| Spindle Rotating Speed (rpm) | Forward: 79, 137, 213, 223, 366, 384, 604, 1024; Reverse: 51,144 |

| Cylinder Pulling Force (KN) | 300 |

| Cylinder Feeding Force (KN) | 142 |

| Cylinder Feeding Stroke (mm) | 1000 |

| Max. Single-Wire Hoisting Force (KN) | 130 |

| Winch Hoisting Speed (m/min) | 0.57-7.58 |

| Steel Wire Diameter (mm) | φ21.5 |

| Retracting Cylinder Stroke (mm) | 690 |

| Electric Motor | Y2280M-4 Type, 90KW |

| Diesel Engine | 6BTA5.9-C180 Type, 132KW |

| Weight (t) | 7.8 |

| Dimensions(L×W×H) (mm) | 4049×1754×2593 |

-

- XB2000A Rotary Core Drill

- XB2000A type core drill is a rotary-table type drilling machine. It can match hard alloy and press wheel drilling bits. This rotary drilling rig can be used in vertical drilling and inclination drilling within 45degree. This product is an ideal choice for deep-hole exploration. It has a mechanical transmission system. This type of drilling machine is widely applied to oil, natural gas and Coal bed Methane exploitation and geological prospecting of solid mineral deposit. XB2000A type core drill can also be used in the drilling ...

Español

Español  Português

Português  Русский

Русский