- Hydraulic Core Drill

- HCDU-5 Hydraulic Core Drilling Rig

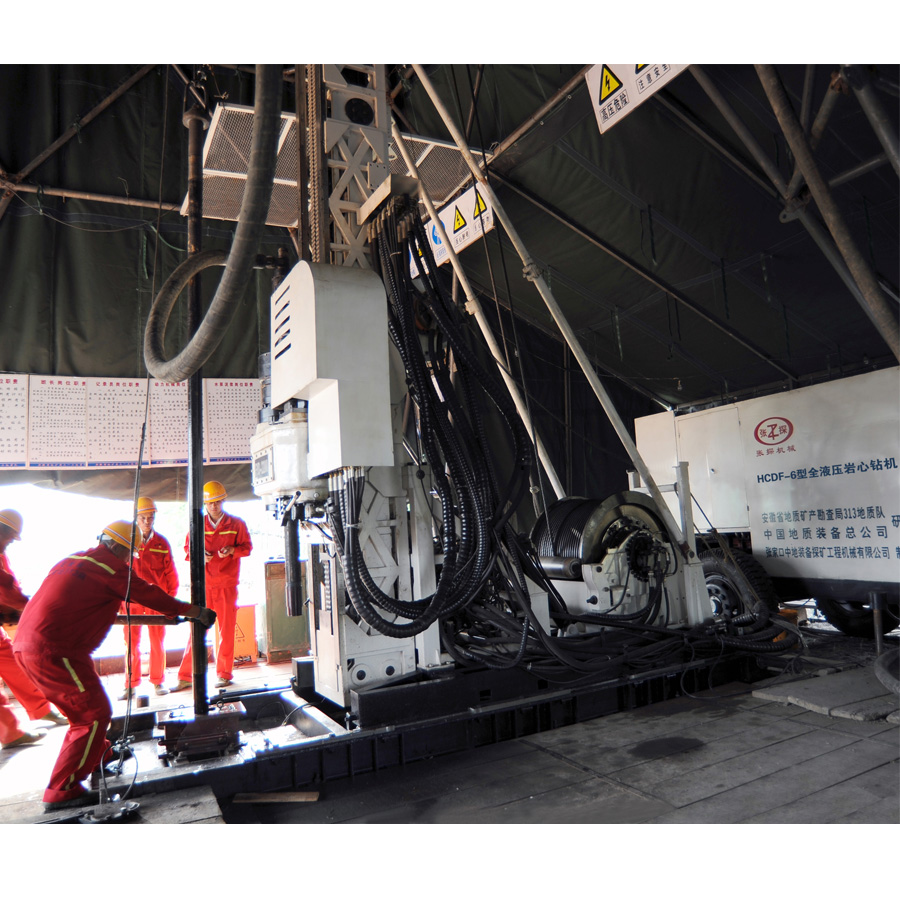

- HCDF-6 Hydraulic Core Drilling Rig

- Spindle Type Core Drills

- Core Drill Rig

- Drilling Rig for Geothermy,Water Well and Coalbed Methane

- Coal Bed Methane Drilling Rig

- Water Well Drilling Rig

- Geothermal Drilling Rig

- Truck Mounted Drilling Rig

- DPP100-4 Truck Mounted Drilling Rig

- Engineering Drill Rig

- GPF2000D Engineering Drilling Rig

- Mud Pump

- BW1200A Mud Pump

- 3NB1300 Mud Pump

- Drill Tower

- SG Series Drill Tower

- AG Series Drill Tower

- Fishing Tools

- Recovering Taps

- High Speed Drilling Swivel

- Drill Hydraulic Jack

- NY-3 Hydraulic Screw Machine

- Petroleum Machinery

- ZP175 Drill Rotary Table

- Sucker Rod and Sucker Rod Coupling

- Chemical Industry Machinery

- Pressure Vessel

- Steel Structure Products

HCDF-6 Hydraulic Core Drilling Rig with Dill depth upto 3000M

HCDF-6 type hydraulic core drilling rig is specially developed for deep-hole drill. It has a drilling capacity upto 3000 m (BQ). The quadrangle derrick and the full hydraulic main machine are separately arranged. This hydraulic drilling machine is composed of diesel engine, feeding system, hydraulic system, control system, main winch, wire line winch, unit head and wellhead clamp. HCDF-6 type hydraulic core drilling rig mainly applied to the exploration in the fields of mining geology, environmental geology and engineering geology. It is widely used in the exploration projects of geological minerals, coalfield, nonferrous metals, nuclear industry, gold and other fields.

Features1. This hydraulic core drilling rig has the characters of long stroke feeding and stable pressure. Drilling accidents has been reduced and drilling efficiency has been improved.

2. Infinitely variable speed is available. This hydraulic drilling machine has a wide range of speeds. It can change the speeds smoothly.

3. This hydraulic core drilling rig has overload protection. It can realize large torque at low speeds.

4. This machine has large normal diameter chuck. It is suitable for PQ, HQ, NQ and BQ drilling construction.

5. With the independent operation platform, the operations are very convenient. Monitoring instrument is used for monitoring the whole operation and working condition inside the holes.

6. Key parts of the hydraulic core drilling rig are reliable. Hydraulic pump, valves and motor are from famous suppliers.

7. Accessories like gripper, mud pump and stirrer are all hydraulic controlled.

8. This hydraulic drilling machine has reserve the advantages of hydraulic drilling rig and absorbed the advantages of high drill tower used in deep-hole drilling rig.

9. The feeding cylinder of the hydraulic core drilling rig has great pulling force. Its feeding stroke reaches 4.8 m. It is suitable for 3m rope and 4.5 m rope.

10. The coring drill rod can achieve a whole pipe core just in one roundtrip. This character helps improving the coring efficiency.

11. With the combination of mechanical gear shift and hydraulic speed governing and function of electric digital display, speed of this hydraulic core drilling rig can be varied accurately and infinitely between 0 and 1200 rpm.

12. The hydraulic chuck of this hydraulic drilling machine is safe and reliable. It has five hard alloy clips inside. Its maximum clamping force reaches 360 KN. It is very convenient to disassemble and change different clips units.

13. This hydraulic core drilling rig also has a standby upper section of the mast. One machine can achieve two purposes.

This hydraulic drilling machine can be delivered to clients place within 30 days in general.

Parameters| Drilling Capacity of this Hydraulic Drilling Machine | |

| Drilling Depth | BQ(55.6mm): 3000m, NQ(69.91mm): 2200m, HQ(88.9mm): 1500m, PQ: 900 |

| Main Electric Motor ( Model/Power/Rotating Speed) | Y3l5M- 4/132 kW/1500 rpm |

| Auxiliary Motor (Model/Power/Rotating Speed) | YI32M- 4/11 kW/1500 rpm |

| Main Pump (Flow/Pressure) | 2l0×2 L/min / 32 Mpa |

| Auxiliary Motor (Flow/Pressure) | 39L/min / 30 Mpa |

| Hydraulic Oil Tank Volume | 600 L |

| Unit Head of Hydraulic Core Drilling Rig | |

| Gear I (Rotating Speed/Torque) | 0-367 rpm / 5960-3800Nm |

| Gear II (Rotating Speed/Torque) | 0-1200 rpm/l820-1166 Nm |

| Main Shaft Normal Diameter | φ117mm |

| Speed Adjustment Mode | Variable speed motor and last stage gear transmission speed control |

| Hydraulic Chuck Structure Type | Spring clamping, hydraulic loosening |

| Amount of Clips | 5 (easy to assemble and disassemble) |

| Clamping Capacity | 220 kN |

| Feeding System | |

| Feeding Stroke | 4800 mm |

| Feeding Force/Pulling Force | 100 kN/200 kN |

| Main Winch | |

| Single Wire Pulling Force | High gear: 96 kN; low gear: 148 kN |

| Hoisting Speed | 120 m/min, 78 m/min |

| Steel Wire Diameter/Rope Capacity | 24 mm/130 (φ24 m steel wire) |

| Line Winch of Hydraulic Core Drilling Rig | |

| Single Wire Pulling Force of First Layer | 11 kN |

| First Layer Wire Speed | 140 m/min |

| Outermost Wire Speed | 550 m/min |

| Rope Capacity | 2500 m (φ5mm steel wire) |

| Main Machine Backward Shifting Distance | 500 mm |

| Overall Weight | 22 t |

| Dimensions (L×W×H) | 10660×2500×2600 (mm) |

Related Products

-

- 3NB1300 Mud Pump

- 3NB1300 type mud pump is a horizontal three-cylinder piston pump. This single function pump has the advantages of mature structure, reliable operation and easy maintenance. This pump can fulfill the requirement of the high pressure jet drilling technique in drilling 2500-3500 m borehole. This pump is manufactured in strict accordance with the SY5138 standard of the state petroleum department. The finished products are tested according to the standard. 3NB1300 type piston pump mainly consists of power end and hydraulic end.

Español

Español  Português

Português  Русский

Русский