- Hydraulic Core Drill

- HCDU-5 Hydraulic Core Drilling Rig

- HCDF-6 Hydraulic Core Drilling Rig

- Spindle Type Core Drills

- Core Drill Rig

- Drilling Rig for Geothermy,Water Well and Coalbed Methane

- Coal Bed Methane Drilling Rig

- Water Well Drilling Rig

- Geothermal Drilling Rig

- Truck Mounted Drilling Rig

- DPP100-4 Truck Mounted Drilling Rig

- Engineering Drill Rig

- GPF2000D Engineering Drilling Rig

- Mud Pump

- BW1200A Mud Pump

- 3NB1300 Mud Pump

- Drill Tower

- SG Series Drill Tower

- AG Series Drill Tower

- Fishing Tools

- Recovering Taps

- High Speed Drilling Swivel

- Drill Hydraulic Jack

- NY-3 Hydraulic Screw Machine

- Petroleum Machinery

- ZP175 Drill Rotary Table

- Sucker Rod and Sucker Rod Coupling

- Chemical Industry Machinery

- Pressure Vessel

- Steel Structure Products

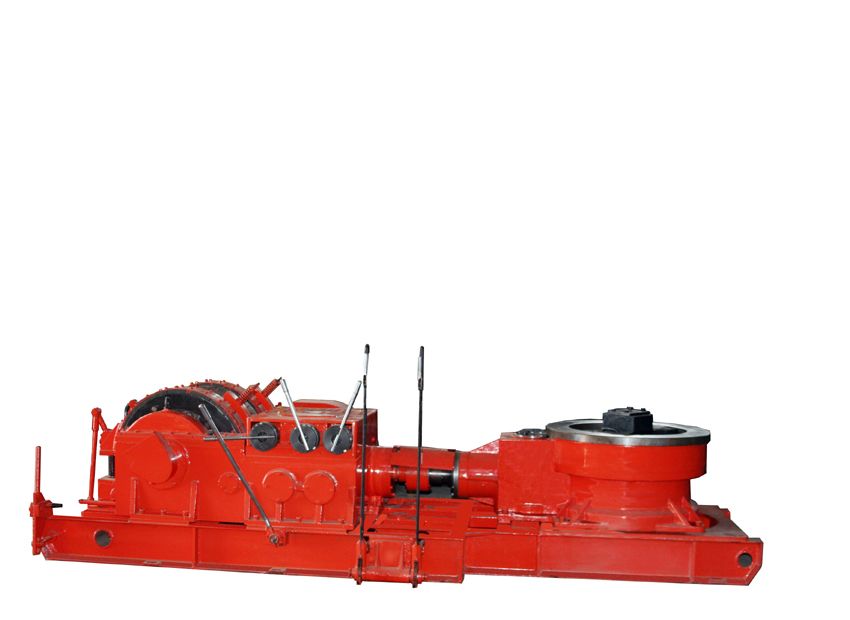

SPS1000 Rotary Drilling Rig for Water Well (Depth 1000-1300M)

SPS1000 type drilling rig is a rotary-table type drilling machine. It has mechanical transmission system. This rig is mainly used in the exploitation of underground water, shallow geothermal energy, shallow petroleum, natural gas and salt. It has the functions of direct and reverse circulation drilling with mud and multi-process drilling with air.

Main Features1. This Rotary drilling rig has powerful drilling capacity. The single wire pulling force of the winch is 80 kN. When the Φ89 drill rod is used, the drilling depth can reach 1300 m. The drilling depth can reach 1000 m when the Φ127 drill rod is used.

2. Due to its large normal drilling diameter (435 mm), this drilling machine can fulfill water well drilling. Because of its great hoisting capacity, this Rotary drilling rig can fulfill geothermal hole construction.

3. This drill rig can adapt multiple construction technique. The output rotating speed of the rotary table ranges from 48 rpm to 190 rpm.

4. Mechanical cathead and big tong can be used together for screwing or unscrewing the drill tools. Rotary table can also be used for the same purpose.

5. The Y315S-4 type electric motor (110 kW) and 6135AN-1 type diesel engine (150 HP) are both optional as power machine of the Rotary drilling rig.

6. This drilling machine has rational overall arrangement and compact structure.

1. Start the power machine and shut the handle of the clutch. Leave the gearbox idling for a while. When everything is normal without noise, the water well drilling rig can turn to loaded working condition.

2. The Rotary drilling rig should not be left running without supervision. If abnormal sounds or phenomenon appear, operator should stop the machine immidiately and solve the problem.

3. Make sure every part of the drilling machine is well lubricated. The temperature of the bearings and gears shouldn’t exceed 70°.

1. Client should do maintenance works after the geothermal drilling rig is stopped, such as tightening each connecting bolt, adding lubricant to every lubrication point, adjusting the space between friction pieces, handling oil leakage and check the belts.

2. Change the wearing parts and maintain the geothermal drilling rig regularly.

Notice: for specific operation please consult the detailed information in the product manual.

| Drill Rod (mm) | φ73, φ89, φ127 |

| Drilling Depth (m) | 1000-1300 |

| Rotary Table Normal Diameter (mm) | φ435 |

| Rotating Speed (r/m) | 48, 69, 110, 190 |

| Rated Torque (KN.m) | 18, 12.5, 8, 4.5 |

| Winch | |

| Rated Single Wire Hoisting Capacity (KN) | 80 |

| Hoisting Speed (m/s) | 0.84, 1.9, 3.3 |

| Steel Wire Diameter (mm) | 6 × 19 (mm)24 |

| Big Hook | Big Hook |

| Pulley Block Type | 4 × 5 |

| Rated Load of Big Hook (KN) | 800 |

| Big Hook Hoisting Speed (m/s) | 0.11, 0.24, 0.41 |

| Kelly(mm × mm × mm) | 108 × 108 × 12200 |

| Main Machine Weight (t) | About 7 t (excluding power machine) |

| Power Machine | |

| Diesel Engine 6135AN-1 | 150HP /1500r/min |

| Electric Motor Y315S-4 | 110kw/1500r /min |

| Cathead | |

| Water Brake | Duplex water brakes |

| Diameter of Impeller | φ330 |

| Main Machine Dimensions (mm) | 3880 × 1965 × 1290 |

Major Matched Equipment

| Drill tower: Tetragonal type pipe tower and A-shaped drill tower for customers' choice | |

| The drill tower has great loading capability and convenience for installation | |

| Nominal Height of Drill Tower (m) | 24, 27 |

| Nominal Area of Base (m) | 6.5 × 6.5; 7 × 7 |

| Max. Working Load of Crane(KN) | 680 |

| Weight of Drill Tower (t) | 10, 16 |

| Slurry System (consists of BW-1200 type slurry pump, power station and pump pipes) | |

| Pressure of Slurry Pump (MPa) | 3.2, 4.4, 6.2, 11 |

| Discharging Volume (l/min) | 1200, 900, 630, 360 |

| Power of Engine | 75kw/1480r/min, 100HP/1500r/min |

| Inner Diameter of Water Hose (mm) | Φ75 |

-

- Water Well Drilling Rig SPS600

- SPS600 type drilling rig is suitable for the drilling work (within 600 m) in soil, rock and gravel layer. It can be used in the drilling of water well and the exploitation of shallow geothermal energy, petroleum, natural gas and salt. Mechanical transmission is adopted in this rig. Rotary table is used to drive the drill tools. This water well drilling rig has a main winch and an assistant winch. Trussed A-shaped derrick or quadrangle derrick is used as drill tower.

Español

Español  Português

Português  Русский

Русский